Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

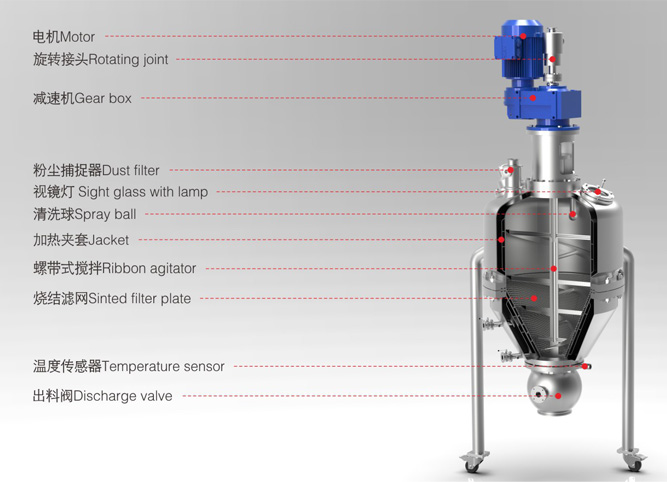

◆Excellent product discharge performance with negligible product hold-up due to the conical bottom,

◆Close agitator to wall /bottom clearances and a unique agitator design.

◆The agitator permits uniform mixing of the entire product mass, without the formation of lumps or balls. The slow rotation of the agitator minimizes the shear forces applied to the product, thus limiting mechanical and thermal product degradation, maintaining the products original crystal structure.

◆The surface area for heat transfer is maximized for optimum performance and cycle times.

◆In compliance with cGMP and FDA guidelines, also in aseptic /steam sterilizable versions:

◆Agitator supported by the top head, with the seal in contact with the vapors only.

◆Entirely welded agitator design, without any bolts, with all edges rounded for good cleanability.

◆Excellent cleanability using CIP Systems, with simple validation process.

Design Code | GB/ASME/PED/AD2000 etc. |

Product volume | 135-14000 liters |

Operating temperature | -10 to 151°C (15 to 300°F) or per requirements |

Operating pressure | -1 to + 6 bar (g) (FV to 90 psig) or per requirements |

Product wetted material | Stainless steels,Duplex stainless, Nickel based alloys such as Hastelloy C22/C276, Titanium, etc., |

Sealing materials | PTFE gaskets, O-Rings in FFKM or FEP encapsulated |

Area classification | GB/ATEX/UL/GOST |

Heated areas | All product wetted components, dust collector, including agitator shaft and blades |

Accessories | Dust filter with automatic backcleaning, sampling valve,CIP system, sightglass with lamp,vacuum system with condenser, heating and cooling unit etc. |

Controls | Control cabinet, HMI,MCC, interface for DCS, can realize computer verification. |

Documents | DQ,IQ,OQ,PQ operate manual,DQ,IQ,OQ,PQ |

Model | Diameter (mm) | Filter area (m2) | Full volume | Equipment width | Total height of equipment | Motor power | Equipment net weight |

JTNB-T550 | 550 | 0.4 | 0.135 | 750 | 1850 | According to the | 0.7 |

JTNB-T700 | 700 | 0.7 | 0.32 | 1100 | 2500 | 1 | |

JTNB-T1000 | 1000 | 1.4 | 0.87 | 1280 | 2850 | 2.3 | |

JTNB-T1200 | 1200 | 2.1 | 1.5 | 1630 | 3500 | 2.7 | |

JTNB-T1400 | 1400 | 3 | 2.5 | 1850 | 4150 | 3.5 | |

JTNB-T1600 | 1600 | 3.8 | 3 | 1900 | 4200 | 4.3 | |

JTNB-T1800 | 1800 | 4.8 | 5 | 2300 | 4800 | 5.7 | |

JTNB-T2000 | 2000 | 6.1 | 6.2 | 2500 | 5800 | 8.4 | |

JTNB-T2200 | 2200 | 7.3 | 8.5 | 2700 | 6300 | 10 | |

JTNB-T2400 | 2400 | 8.8 | 10.8 | 3000 | 6800 | 13.6 | |

JTNB-T2600 | 2600 | 10.2 | 14 | 3200 | 7200 | 17 |

Note: Equipment of different specifications can be designed according to the special needs of users.